|

|

|

| My shop is like a lot of others, there are all sorts of special fixtures, holders, jigs, and storage devices scattered about the shop. Presented here are a few that I am willing to admit that I have. |

|

These are a couple of bench dogs I made the help hold stock on

the bench for belt sanding. I have two, one has a flat section about 1/2"

thick, the other is about 1/4" thick. Two 3/4" dia. dowels are spaced

16" apart and that matches up with the dog hole spacing in my bench top. These were made from scrap, that is why they do not span the bench top completely. |

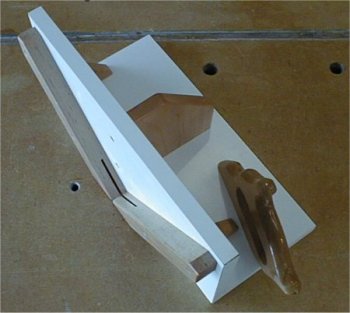

| This is a push block I use for my jointer when doing

face-jointing operations. It allows me to push the stock though with one hand and

keep the outfeed end of the stock flat against the table. My face jointing improved

once I started using this aid. It has also come in hand at the shaper and bandsaw on

occasion as well. It's a very simple tool, just a 4x4 piece of scrap with a simple handle. Some time in the future I'll make an elaborate version of this - just for the fun of it. |

|

|

This is a spline jig. Primarily these are used to cut the

slot on the corner of a mitered picture frame to insert a spline which is later trimmed

flush, these are nearly always cut on the tablesaw. The Maple pieces on the face hold the frame in a 45 degree position relative to the table, the frame should be clamped to the upright base. The whole jig is then run along the edge of the rip fence to cut the joint. |

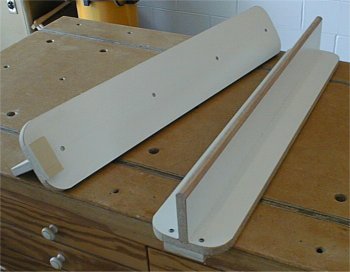

| This is a very common bench jig. They are sometimes

referred to as horses but I call them stand-offs. These are made of 3/4" MCP

because it is easy to clean glue drips off of it and to brighten them up as well. The top edge has a beveled hardwood strip applied for durability, the edges are sealed. Attached to one end is an angled cleat installed so these can be hung on the cleats along the walls of my shop. |

|

|

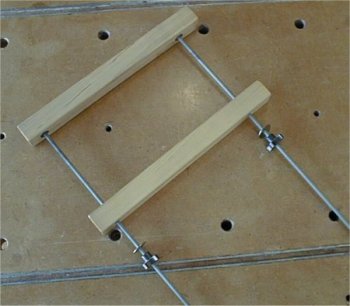

This is an example of a shop-made clamp.

The concept is very simple, two pieces of threaded rod are secured to one wooden clamp bar

while the other is free to move along the length of the rod. On the opposite side of the moveable bar are two speed-nuts. These nuts are specially made such that when loosened, they can be shoved into position very rapidly because they do not engage any of the threads. When they are tightened down though they will automatically re-engage the threads. |

| Note that the placement of the rod is not

symmetrical. This allows another clamp like it to be placed 90 degrees to this one

without interfering with it. These clamps are useful for box glueups however I don't actually use these very often. |

|

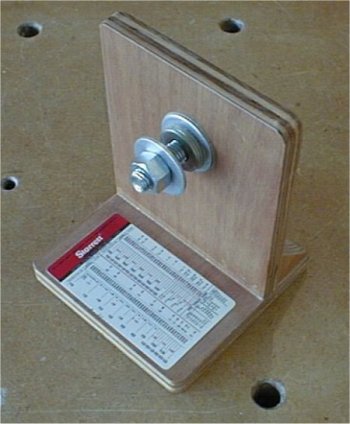

| This is a very simple jig to hold a stacked dado blade set in

order to measure it before putting it onto the saw. This may be useful if the size

of the groove required needed to be very precise and shims were used to get to the desired

width. This type of setup would be easier to do before putting the blades on the saw since there is a lot more room to work in. |

|

|

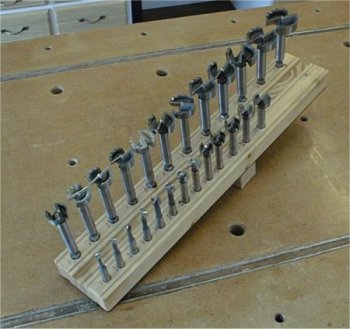

This device is a simple holder for my Forstner bits. It

hangs from a wall cleat near the drill press. The block underneath makes the whole

assembly tilt at an angle relative to the wall; this ensures the bits don't accidentally

leave their post. An important tip for almost any type of storage device such as this is to provide a dust relief. Not visible in the image is a groove that would keep any un-occupied hole free of dust-like debris. |

|

This is a jig used to make the shelf pin holes in cabinets

sides. This jig is nothing more than a series of incrementally spaced 1"

diameter holes in a piece of scrap plywood. The 1" diameter matches a guide bushing for a router. To make the holes I:

It behooves one to make sure that this is done BEFORE the cabinet is assembled {DAMHIKT} and to double check the jig alignment. If this is done the holes will be crisp and clean and line up with opposing cabinet sides. |

| This is one of many crosscut sleds I have made. This model is a double runner design. The bottom is made of 1/4" hardboard laminated on both sides with Formica. The fence is equipped with a measuring tape and stop block. The stop block is held tight to the fence with a toggle clamp. The maximum width this sled would accept is 12 1/2", more than enough most of the time. Using the stop block, the crosscut capacity was about 34". |  |