|

|

|

| The

Question Once in a while the "buy a cnc versus build a cnc" question will pop up on a woodworking, craft, or CNC forum. The poster obviously has done a bit of research, they know about what it costs to buy a machine and that a shop-made machine can also be built for less. Obviously a CNC router is a pretty sophisticated machine, note that these kind of questions don't pop up concerning other common craft tools. For instance, nobody asks if they should buy or build their own tablesaw - do they? What then makes for this question? In a single word, cost, CNC routers of just about any type are pretty expensive, even the small or lower end ones. |

|

The

Short Answer Should you "buy or build"? The short answer is to buy. More people buy a machine than build one. In all likelihood your situation is probably more similar to others who are buying as opposed to building. When I say "buy", I mean from some main stream, well known and established provider. The real question then for most people is "how". The Long Answer If the short answer is to "buy", why continue reading? For one, you might still be unconvinced. Secondly, it still might make sense for you to build one and I'll go through each. |

| Buying

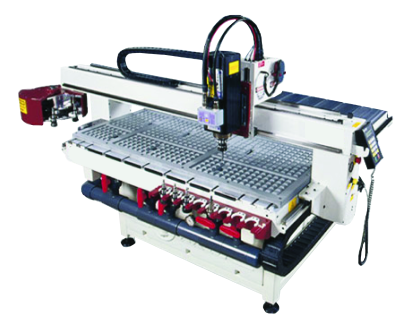

a Machine If you are running a business, buying a machine should be by far a better use of your time. If you are still unconvinced, this is probably a sign that you don't know how exactly you are going to employ the tool and make it profitable for you. If that is the case, I would strongly urge you to figure that out first. Running the numbers should basically make the decision for you. In a business venture, you want to buy from a good vendor, one that can provide support and service when you need it. If your CNC is making you several hundred dollars an hour, you need to be able to get that machine back on line should it break or you have a problem. This is the PRIMARY reason for purchasing a machine, so you can virtually guarantee that it will be running with as little down-time as possible. |

|

| If you buy

from a less well established vendor, that does not mean you are getting an inferior

machine. In all likelihood you will be getting less support however. That translates

directly into "risk", something you would prefer to avoid. The way to evaluate

this risk is simple. Take the difference in price from similarly capable machines from an

established vendor and one that is not and ask yourself if you would pay that amount of

money for better support to get a machine up and running. Remember, every hour the machine

is down is costing you money. If you are running a business and still unconvinced, the high cost is probably a prime factor. In that case, you should find that you have the option to lease a machine or take out a loan of some kind. The used marked is also something that you could look into. There is some inherent risk in a used machine however. Again, if you don't know how exactly you are going to employ the tool and make it profitable for you, you need to have this figured out first. Here again, running the numbers should basically make the decision for you. Maybe you aren't a business, but you still want a CNC machine. The answer for you still may be to buy one. By buying a machine you avoid a lot of the time that would be spent on research, engineering, labor, and re-engineering that comes from building a machine. You'll also have good support from the vendor as opposed to a bunch of helpful suggestions from people who don't have your one-of-a-kind machine. |

|

| Building

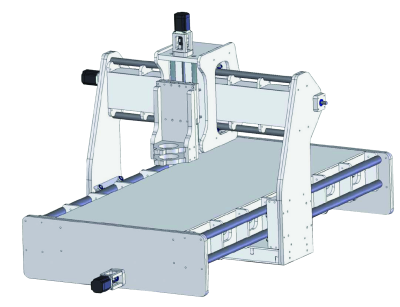

a Machine So you are still considering building a machine. There are people for which building machines like this is their hobby. There's nothing wrong with that, those people have all the justification they need to build their own. For the rest of us, the primary reason for building a machine is cost; we just can't justify the $4k - $8k - or possibly much more on such a machine, no matter what it does; but we would really like to have one. The good news here is that it is doable. Even though a CNC router is a very complicated machine, there are several people who have done it and there is a large body of knowledge out there to help you through all the details. As a general rule, if you choose wisely you should be able to build a system for somewhere between 1.5x to 4x less than a similarly sized commercial machine. |

|

| The bad news is twofold. First, it's

still going to be costly. The more pre-engineered components you buy, the costlier it will

be (but less risky as well). Secondly it will take quite a bit of research and engineering

time. The build time can be pretty reasonable unless you are making most of the components

from scratch. Aside from the potential cost savings, the up side to building your own is that you are very familiar with it and would be able to repair it quickly should the need arise. The caveat I will offer on building a machine is that above all else, the chassis and bearings must form a VERY rigid structure. I would submit that this is the common failing of most first time builders and the reason many end up building a second machine. |

| Summary "Buy or Build"? Buy one if you are a business or don't want to spend a lot of time in research and engineering. Build one of you just can't justify the expense and have the wherewithal to figure out how to do it. |