|

|

|

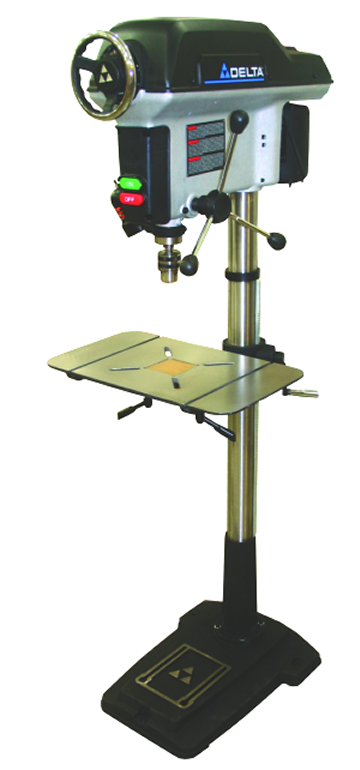

| Description The Delta 20-950 20-Inch Variable Speed Drill Press is a rather large machine for a drill press, definitely a physical step up from the more common 16 inch models. The Delta is one of the few drill presses specifically marketed towards woodworkers, the Delta is the top of the size class in this particular format. The machine is made in China. With an overall height of 75 inches, the machine is tall, weighing in at 286 pounds, it's heavy also (for a drill press). The machine comes equipped with a typical keyed chuck capable of holding shanks up to 5/8 inches in diameter. The 1.0 hp induction motor can spin tools anywhere between 200 and 2500rpm. The large 20 inch swing (meaning it will bore a hole in a 20" dia circle - or 10" of throat depth) makes it quite useful. The 3.18" column diameter is the same as some smaller machines. Instead of the typical small diameter round table, the machine has a larger rectangular table capable of compound angles meaning it can be tilted left / right and also forward. The table has four clamp slots, two t-slots, and a replaceable center section with a through hole. A large control wheel at the front of the machine is used to set the speed via a mechanism attached to the drive pulleys. Basically, the belt location is changed on a variably sized pulley which sets the actual rotary speed of the chuck. This isn't a new concept but differs from the usual manually changed step pulleys of cheaper machines and the electronically controlled speeds found in much more expensive machines. |

|

| Background

For reasons I've never been able to fathom, manufacturers have greatly ignored the specific drill press features endemic to woodworking. The most obvious short fall is the table design. Most drill press tables are fairly small diameter circles meant to hold a small vise of some sort or accommodate a couple of vise grip clamps. Some don't even have a hole in the center for through drilling. For woodworking, the first thing we need is a much larger table to hold the typically larger or longer parts in our work. A corollary issue is swing. For woodworking, a 16" swing is about the minimum you can put up with, a 16" swing only gets you 8" away from the column. The next thing we need is an easy and quick to adjust speed control. Most

drill presses have 2-3 step pulleys with different belt positions to allow for spindle

speed changes. Most users find this too awkward and only make changes if absolutely

necessary. What this boils down to is that the spindle speed is nearly always wrong or

less than ideal because we just don't want to bother with it. |

|

|

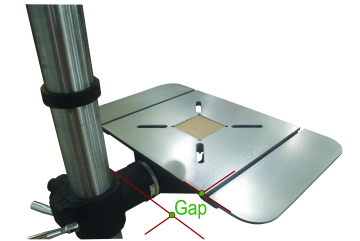

In Use This machine like most all drill presses is very easy to use. The various parts of the design cooperate and work together well in a basic sort of way. The cast iron 24 x 14 table although larger than usual, it still a little on the small size. A typical aftermarket drill press table is 28 x 21 for example. I measured my table to be flat within 0.002". A glaring OEM omission for the table is a fence system. A shop made solution can be made but the table is obviously incomplete without it. As soon as you start thinking "fence", a design problem appears, you basically run out of table well before you would run into the column with any fence system. |

| A nicer feature of the table is it's

ability to tilt left or right as well as down. This will pretty much take care of any

angle drilling needs. There are degree indicators for setting the table but as with most

things, it is better to measure this yourself with accurate measuring tools. A side

benefit of the downward tilt feature is that it is very easy to calibrate the table to be

perpendicular to the spindle. The table has a replaceable square center section, the important feature of this are the built in levelers that ensure this piece is level with the rest of the table. The two t-slots in the table will accept a 3/8" hex head bolt. It will also accommodate 1/4" and 5/16" t-bolts and some t-slot nut profiles. The long 6" quill stroke is one of the best features of the machine. While most of us do not drill too many holes that deep, the long stroke means that the table height does not need to be adjusted as often and can come in handy when drilling the odd-ball object where the chuck cannot get close to the part. The quill also has a lock which can be useful for set-ups or just to set the tool position such as when using a drum sander. On my machine, I measured 0.003" inches of TIR (total indicated run-out) at the chuck, there is some machine vibration evident. |

|

| Although I didn't try it,

the 2" quill diameter should accept the typical mortise chisel attachments. The

spindle is a Morse taper #2 which is pretty standard. The chuck itself is a JT3 which is

decent, an upgrade would be a ball bearing chuck, others will fit too. The drill depth indicator is a large threaded rod on the left of the head opposite the depth handles. It has a large quick-adjust nut for limiting the down stroke, I greatly prefer this type of depth indicator. It would be nice to have a digital readout as well but this machine doesn't have that. The machine is equipped with a flexible work light. A light on a drill press is a very handy thing to have, some drills house the light inside the head casting which makes the machine look less clunky, a flexible light is probably a little more versatile. This light must be plugged into an outlet separately, I think it should be part of the machines electrical system. The switchgear, one of the most used parts of the machine feels pretty cheap, seeing how it's made only reinforces that cheap feeling. |

|

|

The variable speed control works okay and is really the main selling feature of this particular machine. The large hand wheel operates a mechanical system so there is some effort required to affect a speed change. The motor speed never changes but the spindle pulley speed does. There are no "steps" in the speed range, it's continuously variable. The indicator for this wheel isn't super readable or fine but it serves it's purpose, I'm not really expecting fine control over a few rpm's and that really isn't needed. The control has a kind of cheap "rubbery" feel to it though, not incredibly precise, smooth, or easy. |

| Summary I am somewhat disappointed in the overall fit and finish of the machine. I believe the paint job, castings, and switchgear in particular are not indicative of a company's best efforts. If Delta is trying to get back into the game, you cannot tell it from this machine. For a machine touted as specifically designed for woodworkers I think it failed to meet a few of the "ideal" requirements; but for a price it gets woodworkers much closer to it though. There isn't a lot of options for machines such as this.

|